Products & Services

Salem Tube Inc., a subsidiary of Tubacex, manufactures the widest range of stainless & nickel alloy tubing used in a wide array of applications. The company custom produces tubing to many specifications and from 1/8″ to 2″ OD in over twenty five different alloys. This extensive tube offering also includes very quick lead times, long and custom lengths (up to 72′) and in-house comprehensive testing. The competitive global market demands quality and service, and Salem Tube has invested heavily to remain the top redraw manufacturer in the U.S.A.

Salem tube’s laboratory is NADCAP certified. The company offers state of the art finishing lines complete with U.T. testing on site. For over thirty years, Salem Tube has been the proven and trusted source to meet the stringent requirements of the many demanding end users for seamless, welded and drawn tubing.

Instrumentation

Instrumentation tubing has been a large part of Salem Tubes’ product offering from the very beginning. All tubing is provided with a smooth, bright, uniform surface finish in 20′ random lengths (6 meter) or custom lengths also can be provided. Instrumentation tubing is bought and used in a wide variety of applications including panel boards, medical/dental instruments, fuel lines, control lines, and hydraulic lines. Salem Tube offers the following sizes in both 304/304L and 316/316L grades:

| ODs | 1/4″ | 3/8″ | 1/2″ |

| Walls | .035

.049 .065 |

.035

.049 .065 |

.035

.049 .065 |

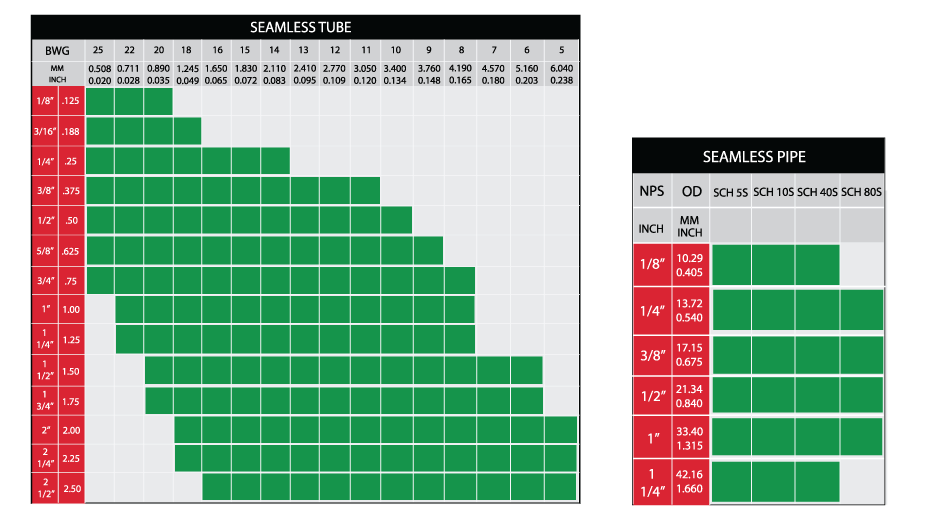

Heat Exchanger

Salem Tube’s heat exchanger tube program encompasses over twenty five alloys from austenitic stainless, duplex stainless steels and nickel alloys. The company’s heat exchanger tube is custom manufactured to each project and is suitable for all types of exchangers including, evaporators, feed water heaters, desalination, condensers, and geo thermal just to name a few.

Salem Tube manufactures heat exchanger tubing in ODs from 5/8″ to 2″ and walls from .028 to .154 and up to 72′ lengths. All of its heat exchanger tubing is provided at competitive prices, quick lead times and tested to countless customer and industry specifications. Salem Tube continues to serve this market with a combination of technical expertise and experience to provide high-performance materials for the most demanding applications.

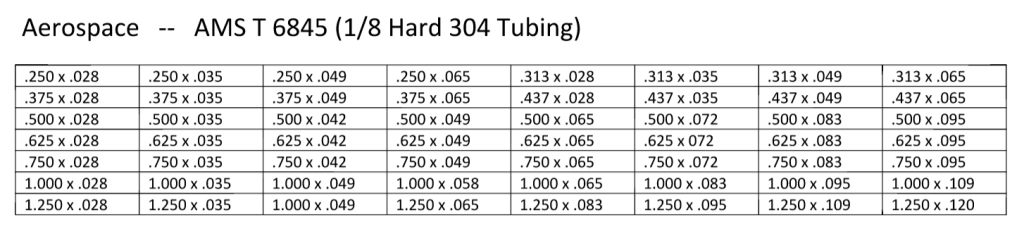

Aerospace

Aerospace companies and their design engineers are held to a very high level of ethics and performance criteria, this industry demands products that meet the most stringent requirements and non-conforming parts would ever be acceptable. The companies that support this market must also manufacture consistent quality and deliver component parts t meet the specific timelines. The strict controls allow for assembly plants to meet the build schedules and perform all the necessary safety checks before delivering the completed aircraft to the final customer.

Salem Tube has been producing aerospace tube products for many years, meeting and exceeding the requirements of this industry. These products are used for numerous applications such as fuel, hydraulic, bleed, and cooling lines, in addition to applications in landing and structural components.

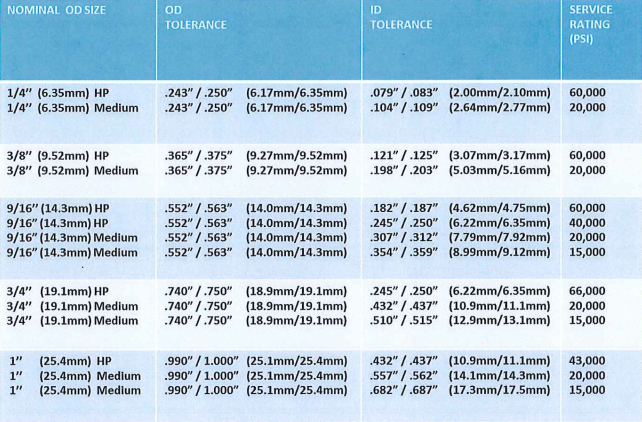

High Pressure Industry

High Pressure products have been used for many years to transport fluids and gasses that are under extreme pressures ranging from 15,000 psi to 40,000 psi but as industry demanded to drill deeper into the surfaces of the earth and cut harder materials the requirements for higher pressures began to push systems to new levels within this industry. 60,000 psi is not uncommon as a standard market request and Salem Tube has positioned itself to be a strong supplier to the customers of this growing market demand.

- Seamless High-Pressure tubes are used in a wide variety of applications using liquid or gas as the pressure medium, such as hydraulic installation and water jet cutting operations

- Pressure tubes are defined by the high yield / high tensile strength in connection with high elongations

Nuclear Quality Tubing

Salem Tube supplies tubing in full compliance with NCA 3800 Nuclear code, classes 1,2,3 and welded safety related. Main applications are heat exchangers and instrumentation product lines. The company is a certified material organization manufacturer, Quality System Certificate holder, number 602 under ASME Boiler and Pressure Vessel Code.

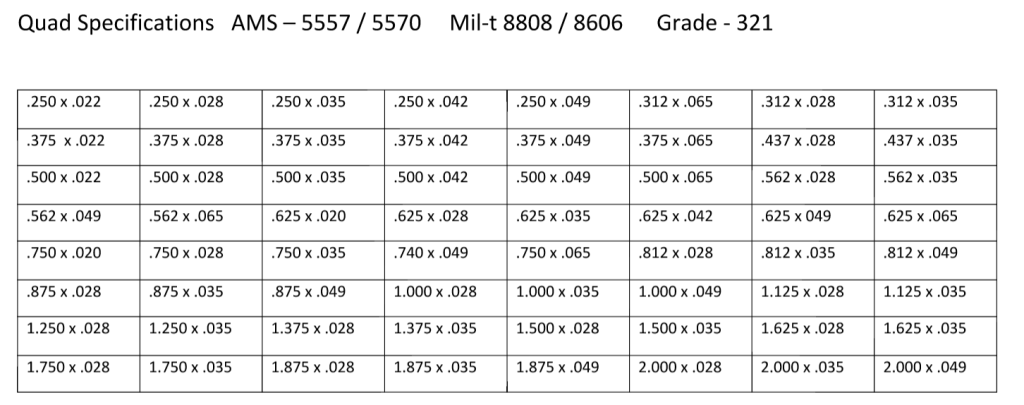

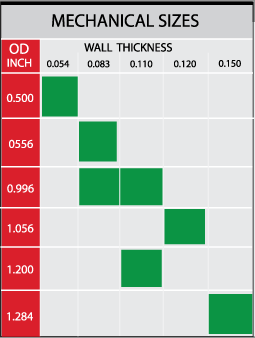

Mechanical Tubing

The supply of refined starting materials for the production of mineral insulated cable. Welded and drawn, as well as seamless tubes, in various size and wall thickness combinations typically used for manufacturing parts where corrosion resistance is required. Some applications are bushings, spacers, push rods, rollers, dental equipment, hand rails, etc. Unlike standard tubing, or pipe sizes, mechanical tubing can be manufactured with tight control of any non-standard OD, ID, or wall thickness dimensions.